Medical and Food Processing

Built to withstand repeated washing and sterilization

Medical and food processing equipment must be durable, smooth, and easy to clean. Acme Wire Products specializes in the custom fabrication of stainless steel components and parts that withstand the high temperatures and harsh cleaning environments – including repeated sterilization – inherent in the pharmaceutical, health care, and food processing industries.

Due to its smooth surface, stainless steel wire protects against nicks and cuts on people, latex and cloth items and provides a better surface for disinfection. The material can be electropolished for a clean, bright surface.

Weld integrity is a primary consideration when specifying wire fabrications. Our internal weld testing procedure assures your parts are consistently strong. Cosmetic arc welding provides a smooth surface that ensures all areas will remain germ-free during cleaning processes. High temperature alloys available.

Basket, pharmaceutical processing

Made from perforated stainless steel sheet metal, this basket, used for sterilizing medical vials, features a hinged welded top and lock. The entire basket was electropolished for a bright smooth finish. Built to withstand repeated washing and sterilization for food processing and medical applications.

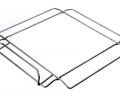

Frame, bakery equipment

To create this hamburger bun “proofing frame,” we used bent and formed stainless steel wire. The frame features two machined hinge pins welded to the frame. All wire forming, arc welding and assembly was done on site.

Washing basket, hospitals

This stainless steel basket, for use with hospital sterilization equipment, features intricate wire forming and subcomponent welding at multiple levels. An electropolish finish ensures the metal’s surface is clean and bright. These types of baskets are frequently used in hospital transport trolleys and medical laboratory furniture. Acme Wire Products also makes stainless steel shelves and racks for laboratory applications.

TESTIMONIALS

We have experienced a partnership with Acme Wire Products for the past decade. They have helped us make our business more successful with their know-how, on-time delivery and outstanding customer service. We could not be where we are today without them.

I would like to compliment Acme Wire Products Co., Inc. on the first class service they provide us. The quality of service, wire & metal products, and extremely competitive prices are excellent. The Staff are very friendly and obliging.

I have worked with Acme Wire Products for over 10 years. Within these years we have posed many unique and challenging designs and concepts. The entire team at Acme Wire is very knowledgeable and always willing to take on these challenges.

Thank you Mike, Ed and your team for the incredible support. It’s like an early Christmas! Thank you for your attention to detail and early fulfillment of commitment. We are pleased with the wireframes received; and will be showing with attached components to management later today.

We have worked with Acme Wire Products for over 20 years and continue to do so. Very responsive and highly professional. The manufactured products they produce are always high quality. They offer engineering services that help develop cost effective designs. I would highly recommend them.

Custom Medical Wire Forming Near Me in Connecticut

Acme Wire Products stands as a premier destination for those seeking top-tier wire basket solutions. Renowned as leading wire basket manufacturers, Acme Wire Products boasts a legacy of excellence, offering customized solutions tailored to meet diverse industry needs. Whether you’re in search of medical wire forming services or custom wire baskets, this esteemed establishment delivers unparalleled quality and precision. For those specifically looking for custom medical wire forming near me, Acme Wire Products emerges as the go-to choice. Their state-of-the-art facilities and seasoned experts ensure that each project meets stringent medical industry standards. Located conveniently for those in Connecticut, the company’s specialized services in medical wire forming CT have garnered acclaim for their precision and reliability. The importance of precision in medical applications cannot be overstated, and Acme Wire Products understands this implicitly. With a commitment to excellence, they specialize in custom medical wire forming CT, ensuring that each product aligns with exact specifications and requirements.

Whether you’re developing intricate medical devices or requiring specialized wire baskets for healthcare applications, their expertise ensures products that are both durable and efficient. Their local presence, coupled with a broad range of capabilities, allows clients to benefit from personalized consultations and solutions tailored to specific needs. Acme Wire Products stands as a beacon of excellence in the realm of wire basket manufacturing and medical wire forming. Whether you’re situated in Connecticut or searching for custom solutions near you, their dedication to quality, precision, and customer satisfaction sets them apart. Trust in Acme Wire Products for all your wire basket and medical wire forming needs, and experience unparalleled craftsmanship and expertise.