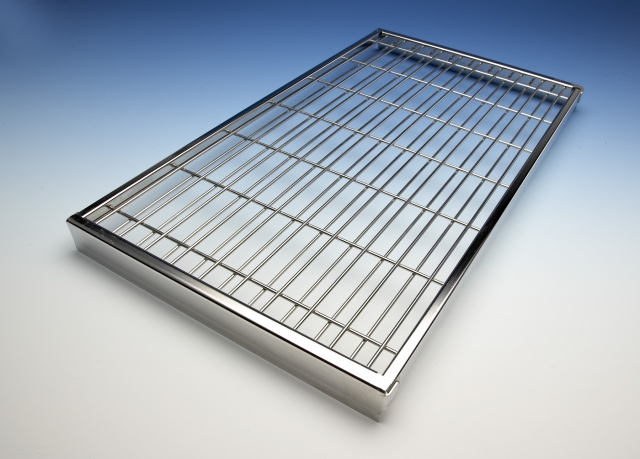

Customers sometimes design a product using steel when stainless steel is a better choice but they may not know the differences and characteristics of stainless steel. This post will provide information on the characteristics and typical applications for stainless steel wire products. What is the difference between stainless and ordinary steel? All steel is carbon based, but stainless steel contains chromium at 10% or more by weight. Steel is susceptible to rust, an active iron oxide film that forms when steel is exposed to air and moisture. This iron oxide film is active and accelerates corrosion by forming more iron oxide. Stainless steel does not rust, or is non-corrosive because of passivity. Passivity is when chromium forms a passive film of chromium oxide to repair the surface layer and prevent further corrosion. Stainless steel’s non-corrosive characteristic gives it a long life span. With the addition of nickel, the material survives even longer and in several types of environments. By adding molybdenum and nitrogen, stainless gains improved resistance to pitting and crevice corrosion. Stainless has a high strength to weight ratio even at high temperatures. It is easy to clean because the surface is non-porous. It is well-suited for medical and food-grade applications because it prevents the absorption of bacteria and germs. Stainless steel does not stain and can be polished to create a shiny, aesthetic appearance. Austenitic stainless steels are identified as the T300 series stainless steels. Typical alloys are T302, T304 and T316. T303 is a machining grade stainless steel and is used when wire ends require threading. Applications for stainless steel wire fabrications can vary but some common examples are kitchen and bathroom accessories, aerospace components, medical device and hospital equipment components, autoclave and sterilization racks, trays and baskets, marine guards, oil & gas equipment accessories, laboratory instruments and food processing and foodservice equipment components. Contact the wire fabrication specialists at Acme Wire Products for input on which material is best suited to your custom application. [email protected] or 1-800-723-7015.